Heavy Duty Cooling Device Cleaning

Heat Exchangers are specifically designed for the transfer of heat from one material or another. There are many types of heat exchangers used today, but one problem remains constant in all of them: fouling.

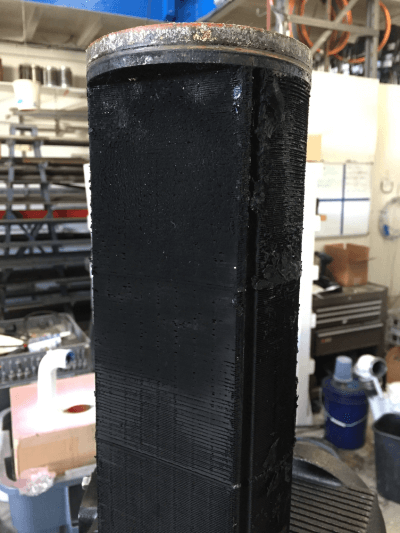

Fouled Plate Heat Exchanger

Fouled Plate

Tube Side Fouling

Shell Side Corrosion Fouling

Fouling is deposits of materials that can accumulate on the exchanger surface in turn robbing them of their effectiveness; causing process energy costs to rise, increase equipment downtime, and ultimately requiring expensive plant outages. Fouling is an on going industry problem estimated to cost the United States more than $4 billion each year.

To deal with potential fouling, companies have gone to the extreme of installing over sized heat exchangers and installing duplicate exchangers to continue operations while the other is in service. Once fouling has occurred, the industry has had to solely rely on the off-site high pressure hydro-blasting, brushing and scraping methods, and by the use of chemical cleaning.

THE HOT FLUSH SOLUTION

The Hot Flush system delivers a fully automated patented process that utilizes high speed reverse flushing, air injection and filtration when necessary.

Since there is no one chemical or form that fits all applications, we provide on-site analysis to determine the type of cleaning solution and system based on the contamination and application.

For a fixed on-site solution, we can set up our reverse flushing technology and filtration system on-site and attach it directly to your system to reduce/eliminate the contamination. We have the ability to custom design machines to meet the specification of each application; including fluid, flow and when necessary, laser particle counting.

Additionally, flushing should be performed as part of a diagnostic point in a proactive maintenance schedule to detect problems before they become catastrophic.

Independent Tests

The Hot Flush machine was tested by an independent party. The Hot Flush machine and a competitor’s flushing machine were tested on coolers that had been removed from vehicles with transmission failures.

The test was unique in that it allowed the competition device to clean the cooler first. Next, the Hot Flush machine was used on the same transmission after the competition had cleaned it. The results of these tests really speak for themselves.

Even after the competition flushed the transmission cooler (and not much was removed) Hot Flush was able to extract a drastic amount of debris that had been missed. This is a great, quick visual illustration of why Hot Flush is such a necessary addition to your oil cooler / heat exchanger maintenance routine.