Why Hot Flusher Matters to Military Aviation

In the high-stakes world of military aviation, every second counts. A clogged FOHE can compromise engine performance, reduce fuel efficiency, or even ground an aircraft—outcomes that simply aren't acceptable for the F-15, F-16, or T-38. Hot Flusher's ability to restore these systems quickly and effectively means less downtime, lower maintenance costs, and greater operational readiness.

As air forces around the globe continue to rely on these iconic aircraft, Hot Flusher remains committed to supporting their missions. Our technology isn't just about cleaning—it's about empowering the men and women who keep the skies safe.

Ready to see how Hot Flusher can elevate your maintenance game? Call to learn more about our worldwide impact and cutting-edge solutions!

The Critical Role of FOHE in Fighter Jets

The Fuel-Oil Heat Exchanger (FOHE) is a vital component in modern jet aircraft like the F-15, F-16, and T-38. It regulates temperatures by transferring heat between the fuel and oil systems, preventing overheating and maintaining engine efficiency during high-speed, high-stress missions. However, over time, these systems can accumulate debris, carbon deposits, and contaminants that reduce performance and threaten operational readiness. Traditional cleaning methods often fall short, requiring lengthy downtime or risking incomplete results.

That's where Hot Flusher steps in. Our advanced flushing technology provides a fast, thorough, and non-invasive solution to keep FOHE systems in top condition—crucial for aircraft that demand precision and reliability at Mach speeds.

Hot Flush in Action: F-15, F-16, and T-38

The F-15 Eagle, known for its unmatched air superiority, relies on the Hot Flush system to maintain its FOHE, ensuring sustained power and agility during combat operations. Similarly, the F-16 Fighting Falcon, a multirole fighter celebrated for its versatility, benefits from our technology to keep its systems clean and responsive, whether in training or active deployment. Even the T-38 Talon, the Air Force's supersonic trainer, uses Hot Flusher to prepare the next generation of pilots with equipment that performs like new.

Across air bases worldwide, maintenance crews trust Hot Flusher to flush FOHE systems efficiently. Our patented pulsation process dislodges and removes buildup without disassembly, cutting maintenance time and costs while extending the lifespan of these critical components. From the deserts of the Middle East to bases in Europe and the Pacific, Hot Flusher is a global partner in keeping air forces mission-ready.

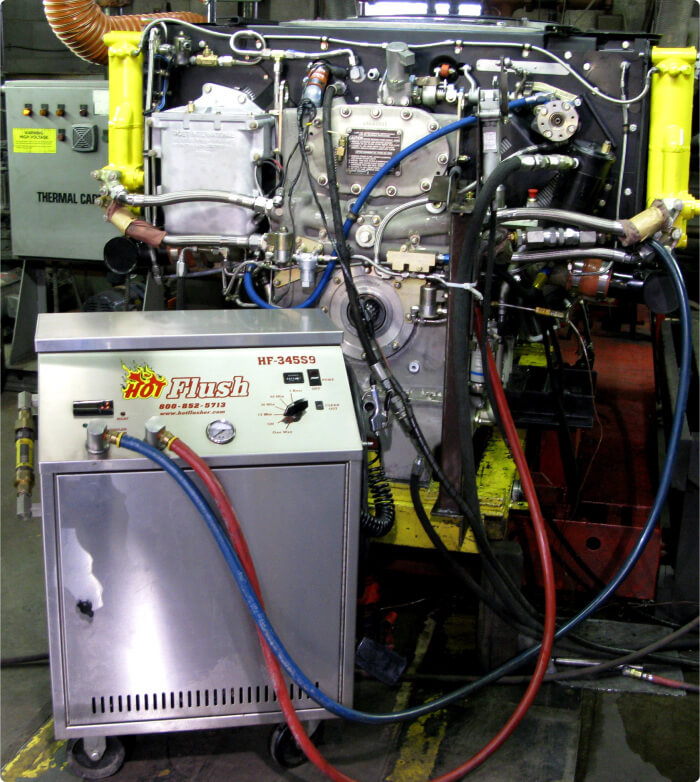

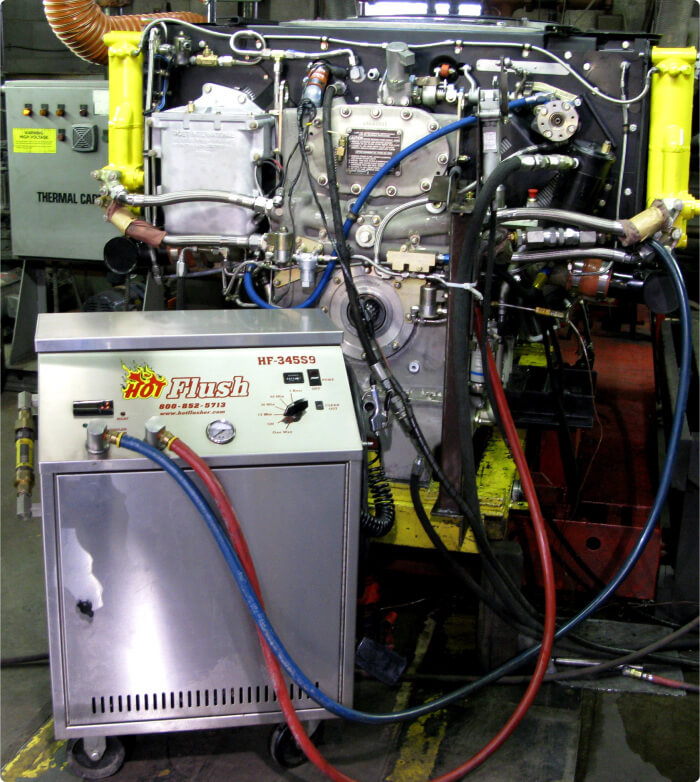

Hot Flush connected to a AVDS 1790 1050HP M88A2 Hercules Engine.

A Legacy of Innovation, A Future of Excellence

The Hot Flush machine's success in military aviation is built on Hansen's pioneering patents. His inventions introduced a game-changing approach to heat exchanger cleaning, and today, owners Tyler Hansen, Jordan Nelson, and Lindsey Valentini are driving that legacy forward. Tyler's technical expertise ensures our equipment meets the rigorous demands of military applications. Jordan's strategic vision expands our reach to air forces worldwide. Lindsey's operational leadership guarantees that every Hot Flusher unit delivers consistent, high-quality results.

Together, they've positioned Hot Flusher as an indispensable tool for aerospace maintenance, trusted by the U.S. Air Force and beyond.